Factory Wastewater & Sewage Treatment Energy-Saving Technology: Spiral Plate Heat Exchanger

Current Challenges

-

Direct Discharge of High-Temperature Wastewater, resulting in severe heat loss

-

High Energy Consumption in wastewater treatment equipment (e.g., heating, aeration, sludge dewatering)

-

Frequent Maintenance of Traditional Heat Exchangers due to scaling and fouling

Improvement Strategies

-

Implement Spiral Plate Heat Exchangers for heat recovery

-

Lower Wastewater Discharge Temperature to reduce thermal pollution

-

Enhance Energy Efficiency, reducing fuel and electricity consumption

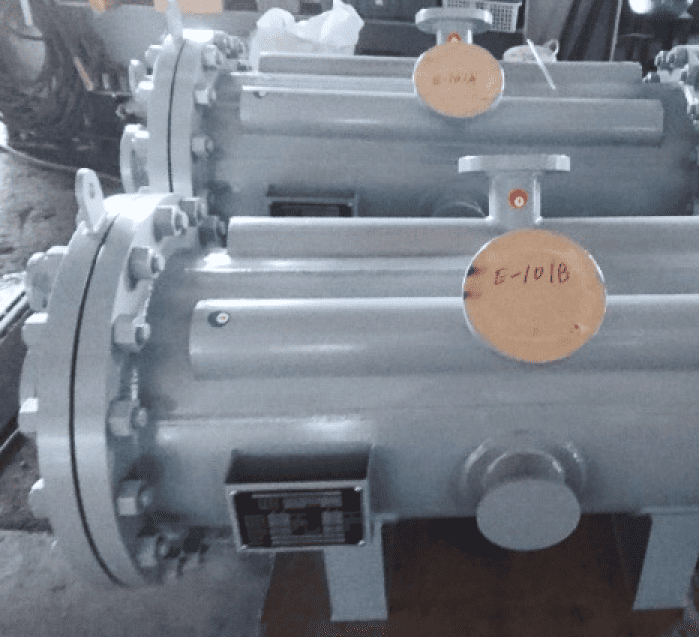

Spiral Plate Heat Exchanger

-

Applications

1. Heat Exchange Between High-Temperature Wastewater & Cold Inlet Water (Enhancing Energy Recovery Efficiency)

2. Heat Exchange in Sludge Treatment Systems (Improving Dewatering Efficiency)

3. Waste Heat Recovery from Wastewater in Chemical & Pulp/Paper Industries (Reducing Heat Loss)

-

Advantages

✅ High Thermal Conductivity (Efficient heat transfer through internal evaporation & condensation in heat pipes)

✅ Turbulent Flow Effect Reduces Scaling, ideal for high-pollution water treatment

✅ Efficient Heat Exchange, maximizing waste heat utilization

✅ Compact Design, suitable for limited installation spaces

✅ Compatible with Corrosive Fluids, with optional anti-corrosion materials