Operating Principle

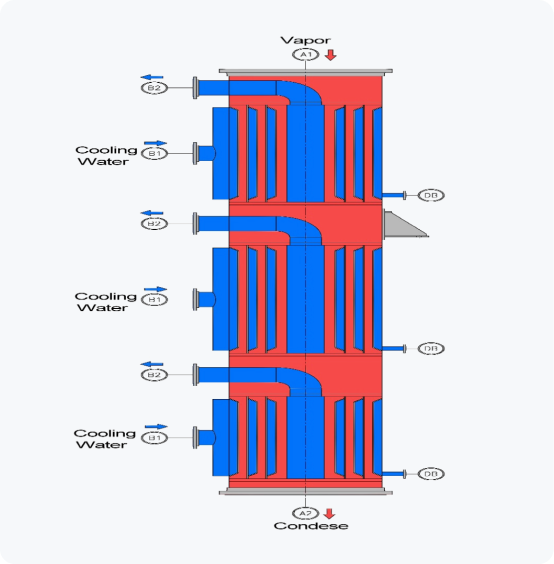

The spiral plate heat exchanger consists of two metal plates wound into a spiral-shaped channel, allowing hot and cold fluids to flow in countercurrent or parallel directions within separate passages. The continuous and extended flow paths create stable turbulence, enhancing heat transfer efficiency while minimizing fouling.

The compact spiral design reduces footprint and effectively lowers pressure loss. This equipment is particularly suited for high-efficiency heat exchange applications in industries such as chemical processing, food processing, and energy recovery systems. It operates reliably under harsh conditions, providing a long-term and efficient thermal management solution.

Key Features

-

Compact structure – Minimal space requirement, ideal for confined areas.

-

Extended flow paths – Large heat exchange surface area for high thermal efficiency.

-

Educed fluid resistance – Lower energy consumption and improved system performance.

Advantages

-

High Overall Heat Transfer Efficiency

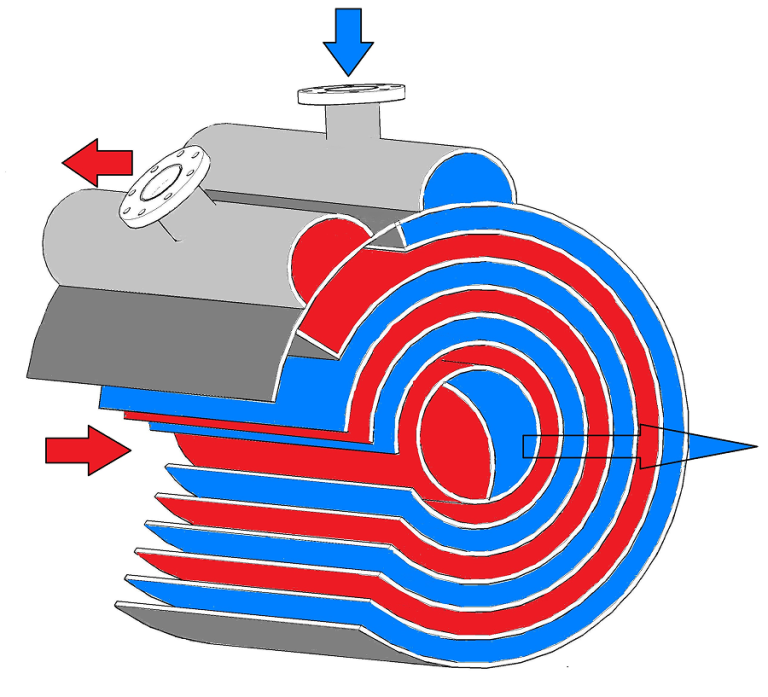

The spiral flow channels in the heat exchanger easily generate turbulent flow, enabling highly efficient heat transfer. (Figure 1)

-

Self-Cleaning Mechanism

A single flow channel combined with centrifugal force creates a self-cleaning effect. Fluids containing impurities or suspended particles reduce cross-sectional area due to sedimentation, which in turn increases flow velocity, preventing deposits from adhering to the surface. (Figure 2)

-

Effective Temperature Differential Utilization

The counterflow design allows for uniform heat exchange even with minimal temperature differences, maximizing energy efficiency.

-

Easy to maintain

Maintenance and cleaning require only opening the end covers, allowing easy access for flow channel inspection and upkeep.

-

Space Saving

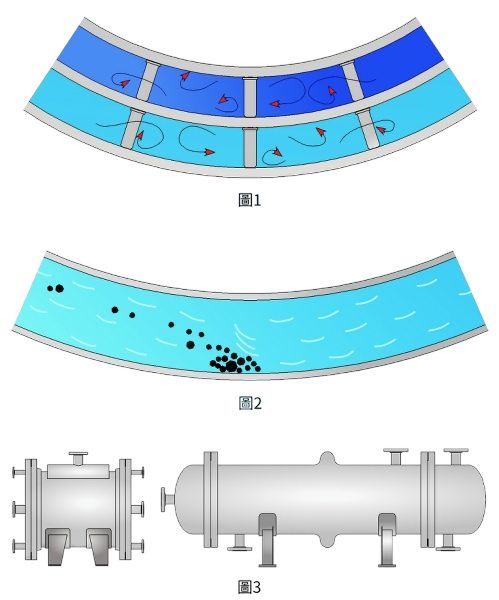

The high-performance structure of the spiral heat exchanger features a compact size, requiring significantly less operational space. Compared to a shell-and-tube heat exchanger with the same heat transfer area, it saves at least 50% of the space. (Figure 3)