High-Efficiency Energy-Saving Technologies for Steel Plants: Applications of Heat Pipe and Spiral Plate Heat Exchangers

Current Challenges

-

High-Temperature Flue Gas Emissions (e.g., blast furnaces, converters, reheating furnaces)

-

Low Efficiency of Traditional Heat Exchangers (Poor heat transfer, rapid fouling)

-

Frequent Maintenance (Affecting production efficiency)

Improvement Strategies

-

Install Heat Pipe & Spiral Plate Heat Exchangers to enhance waste heat recovery

-

Reduce Maintenance Costs and extend equipment lifespan

-

Lower Fuel Consumption and reduce chimney emissions

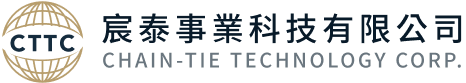

Heat Pipe Heat Exchanger

-

Applications

1. Blast Furnace Hot Stoves – Recovering flue gas heat to preheat combustion air

2. Sinter Plant Exhaust Gas Recovery – Reducing exhaust temperature and improving energy recovery efficiency

3. Converter Flue Gas Cooling – Lowering emission temperature and recovering waste heat

-

Advantages

✅ High Thermal Conductivity (Heat transfer through internal evaporation & condensation)

✅ Adaptable to High-Temperature Environments

✅ Modular Design, allowing individual tube replacement for easy maintenance

✅ Minimizes Ash Buildup & Corrosion, improving long-term efficiency

-

Case Study: The blast furnace exhaust recovery system

1. Installed a heat pipe heat exchanger in the blast furnace exhaust system to recover 300°C waste gas heat.

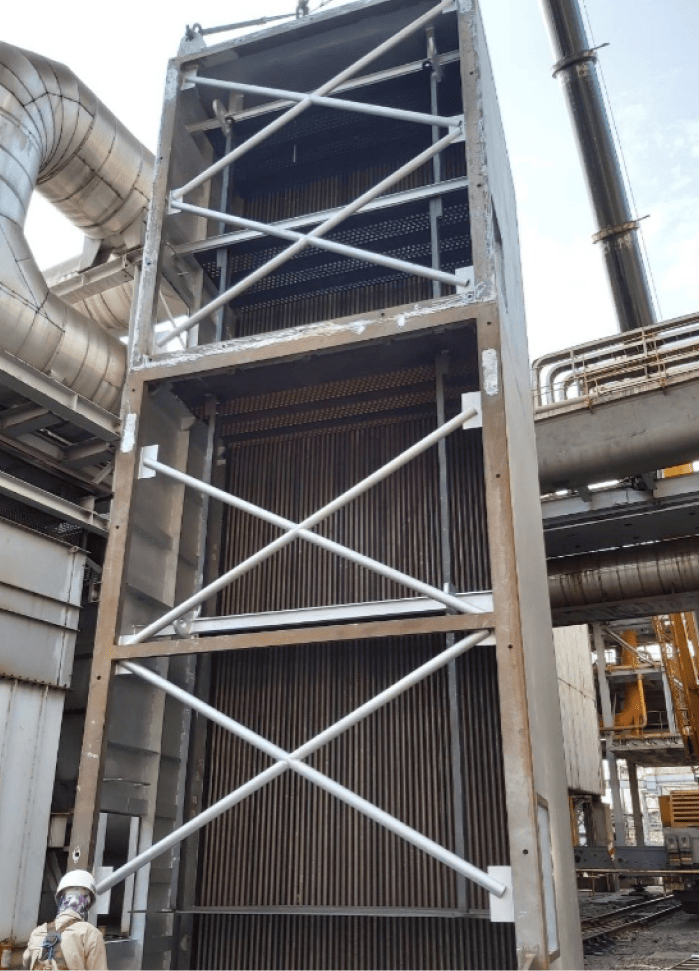

Spiral Plate Heat Exchanger

-

Applications

1. High-Temperature Water Cooling Systems – Minimizing cooling water usage

2. High-Temperature Water Cooling Systems – Minimizing cooling water usage

3. Hydraulic Cooling System in Steel Plate Press machine (improve cooling efficiency)

-

Advantages

✅ High Thermal Conductivity (Heat transfer through internal evaporation & condensation)

✅ 30–50% Higher Heat Exchange Efficiency (Turbulent flow effect from spiral design)

✅ Reduced Fouling, lowering maintenance requirements

✅ Compact Design, suitable for tight installation spaces

✅ Capable of High-Temperature & High-Pressure Applications (Up to 4 MPa)

-

Case Study: High-Temperature Steam Condenser Upgrade with Spiral Plate Heat Exchanger