High-Efficiency Energy-Saving Heat Exchange Technology for Petrochemical Plants: Applications of Heat Pipe and Spiral Heat Exchangers

Current Challenges

-

High-Temperature Waste Heat Emissions

Combustion equipment (boilers, heaters, cracking furnaces) releases a significant amount of heat energy.

-

Low Heat Exchange Efficiency

Traditional shell-and-tube heat exchangers have low efficiency and are prone to fouling.

-

Frequent Maintenance

Scaling and corrosion lead to frequent maintenance, affecting production.

Improvement Strategies

-

Enhancing Waste Heat Recovery Efficiency, Reducing heat loss from chimney emissions.

-

Using High-Efficiency, Energy-Saving Heat Exchange Equipment. Implementing heat pipe heat exchangers and spiral heat exchangers.

-

Reducing Maintenance Requirements. Extending equipment lifespan and improving operational reliability.

Heat Pipe Heat Exchanger

-

Applications

1. High-Temperature Flue Gas Recovery (Boilers, Cracking Furnaces, Combustion Chambers)

2. Low-Grade Waste Heat Recovery (e.g., Steam Condensation Recovery)

3. Improved Heat Exchange Efficiency by 30–50%, reducing fuel consumption

-

Advantages

✅ High Thermal Conductivity (Heat transfer through internal evaporation & condensation)

✅ Adaptable to High-Temperature Environments (Suitable for 200–900°C)

✅ Automatic Temperature Balancing, minimizing local overheating

✅ Modular Design, allowing individual heat pipe replacement for easy maintenance

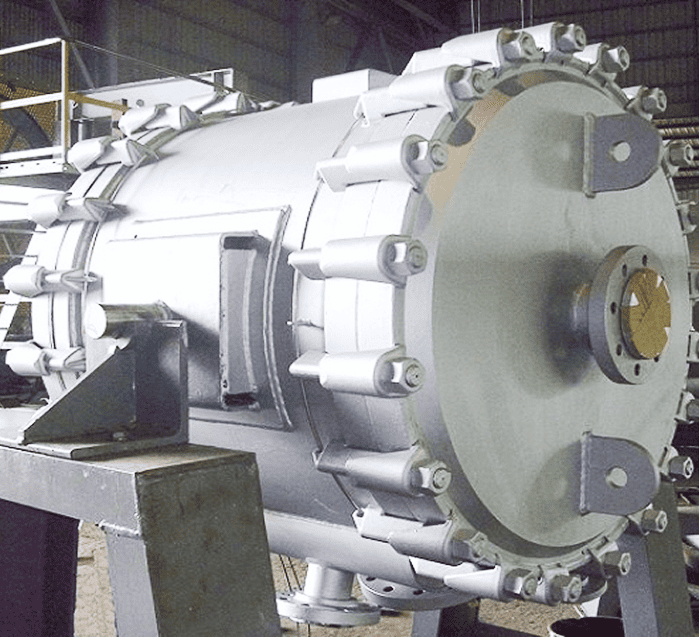

Spiral Plate Heat Exchanger

-

Applications

1. High-Temperature Steam Condensation (Reducing steam loss)

2. Petrochemical Refining Process Heating/Cooling (e.g., hot oil/water cooling)

3. Wastewater & High-Viscosity Fluid Heat Exchange (Self-cleaning effect)

-

Advantages

✅ High Thermal Conductivity (Heat transfer through internal evaporation & condensation)

✅ High Heat Exchange Efficiency (Turbulent flow design with high heat transfer coefficient)

✅ Reduced Fouling (Spiral flow effectively flushes away deposits)

✅ Compact Design, ideal for tight spaces

✅ Minimal Cleaning Requirements, lowering maintenance costs