High-Efficiency Energy-Saving Technologies for Pharmaceutical & Food Factories: Applications of Heat Pipe and Spiral Plate Heat Exchangers

Current Challenges

-

High Consumption of Steam and Hot Water (e.g., sterilization, drying, pasteurization, boiling)

-

Direct Emission of High-Temperature Exhaust Gas, resulting in significant heat loss (e.g., boilers, drying equipment)

-

Rapid Scaling of Traditional Heat Exchangers, leading to frequent maintenance and affecting production stability

Improvement Strategies

-

Install Heat Pipe Heat Exchangers & Spiral Plate Heat Exchangers to enhance heat recovery efficiency

-

Install Heat Pipe Heat Exchangers & Spiral Plate Heat Exchangers to enhance heat recovery efficiency

-

Decrease Heat Exchanger Maintenance Frequency to improve equipment uptime

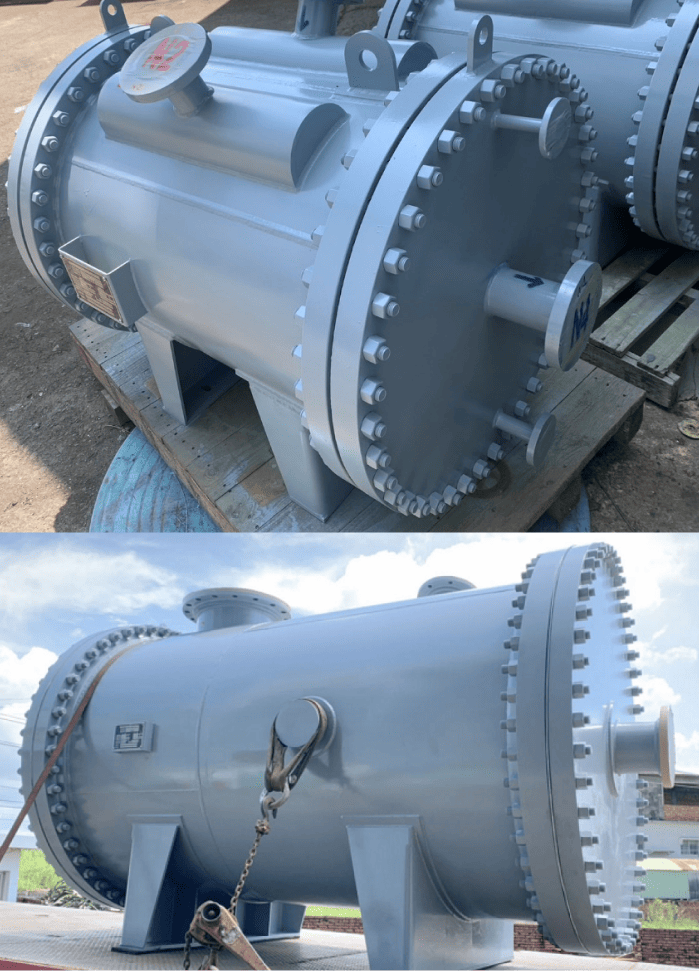

Spiral Plate Heat Exchanger

-

Applications

1. Pharmaceutical Factories: Steam Condensate System

2. Food Processing Plants: Waste Heat Recovery from Pasteurization / Cooking Systems

3. Steam Condensate Recovery

-

Advantages

✅ High Thermal Conductivity (Heat transfer through internal evaporation & condensation)

✅ Increase in Heat Exchange Efficiency (Enhanced turbulence from spiral flow)

✅ Self-Cleaning Design: Reduces fouling and clogging

✅ Compact Size: Suitable for limited installation spaces

✅ Food-Grade & Sterile Applications: Optional stainless steel material for hygiene compliance