Production Types

Tube and shell heat exchangers

Refineries and large petrochemical plants commonly use heat exchangers designed to withstand high-pressure and high-temperature conditions, making them suitable for various liquid-to-gas and liquid-to-liquid heat exchange applications.

Staggered fin-tube heat exchangers

Adding fins to the outer surface of the tubes enhances heat transfer by increasing the surface area and improving efficiency. This design is particularly effective in applications where the heat transfer coefficient is low, such as air and other clean gases.

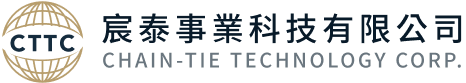

Spiral coil heat exchanger

The spiral coil heat exchanger features spiral-arranged tubing, maximizing heat transfer efficiency. Its compact and high-performance design increases surface area while maintaining consistent heat flow and temperature distribution. Additionally, the smooth flow paths prevent clogging and minimize dust accumulation, ensuring stable operation.

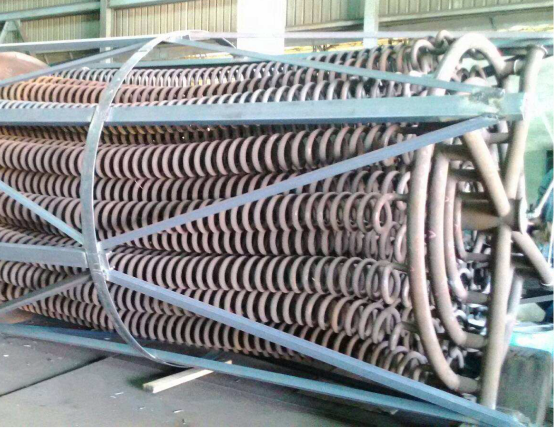

Spiral wounded Heat Exchanger

The spiral wound tube heat exchanger is compact and space-saving, offering high heat transfer efficiency. It features a self-cleaning effect, providing dust and contamination resistance, making it ideal for high-pressure and high-temperature applications while maximizing heat transfer performance.

Cross flow recuperators

This type of heat exchanger recovers waste gas heat to preheat air, making it ideal for combustion air treatment and industrial processes. It enhances overall system energy efficiency and reduces fuel consumption, contributing to cost savings and sustainability.

Electric tube heaters

The electric heating exchanger uses electric heating tubes to generate a high-power heat source for uniform heating. It is suitable for non-contact applications where products are not contaminated, such as drying, de-icing, and heating. The temperature is flexibly adjustable, making it one of the most energy-efficient heating methods.

Pressure vessels and Reactors

Designed and manufactured in accordance with CNS pressure vessel standards, ASME, or JIS standards, including Taiwan CNS industrial inspection regulations and U.S. ASME U Stamp certification.

Towers and Others

The spherical tanks, reaction vessels, and cryogenic tanks are designed and manufactured in compliance with Taiwan's pressure vessel regulations or U.S. API standards, including Taiwan CNS industrial inspection standards and U.S. ASME U Stamp certification.