Operating Principle

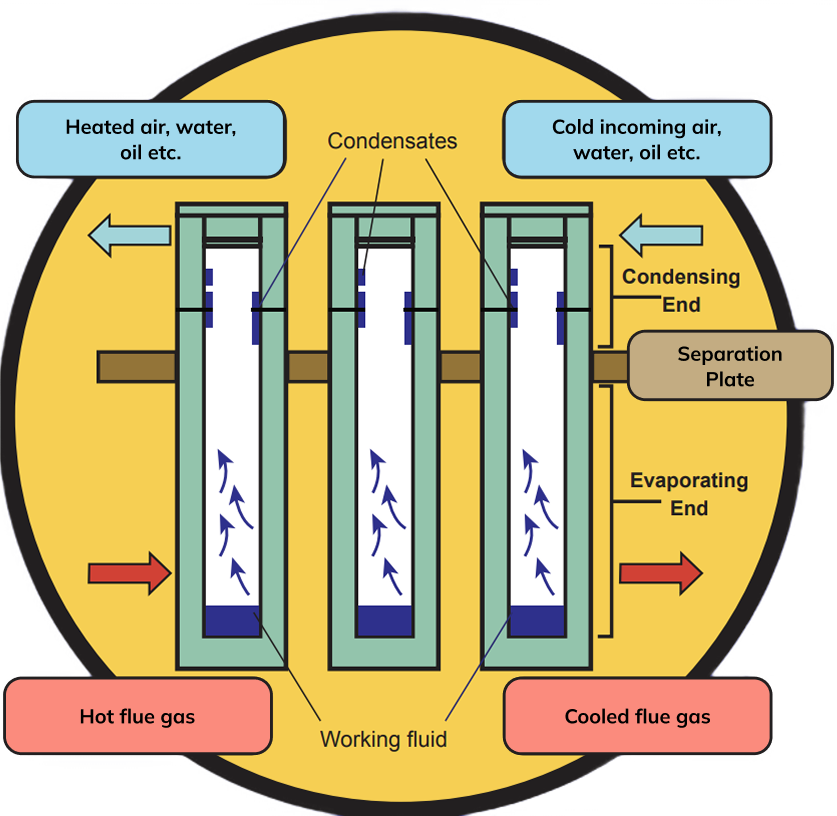

The heat pipe heat exchanger utilizes the principle of refrigerant phase change within a sealed tube to achieve high-efficiency heat transfer.

When the refrigerant absorbs heat, it rapidly evaporates, and the resulting vapor moves to the cold end, where it releases heat and condenses back into a liquid.

The condensed refrigerant then returns to the hot end via capillary action or gravity, completing a continuous evaporation-condensation cycle.

This process requires no additional power, offers exceptional thermal efficiency, and operates with minimal temperature differences. It is particularly suitable for industrial waste heat recovery, electronic cooling, and HVAC systems, significantly enhancing energy utilization and extending equipment lifespan.

Advantages

-

Recovering the Irrecoverable

Many opportunities for real cost savings are being missed in the industrial industry today due to the perception that certain types of waste heat cannot be recovered.

-

Zero-risk industrial waste heat recovery

Our team provides solutions to complex waste heat recovery

applications for industrial users wishing to reduce operating costs

and carbon emissions.

Custom-built solutions

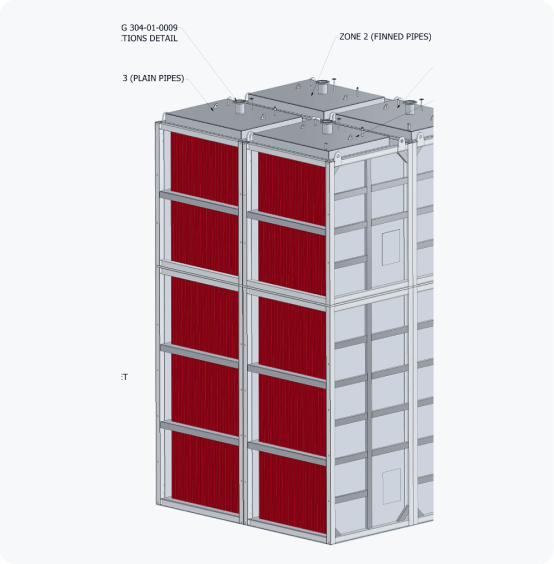

Since 2007, we have delivered our custom-built heat pipe heat exchangers – ranging in size from a few kilowatts to several megawatts – to blue-chip clients in many industrial sectors around the globe.

Including Chain-Tie Technology Corp., assembled the heat pipes exchangers in Taiwan for CPC, CSC(CSMC), CSCC etc. We applied over 8300pcs heat pipes, the longest one is about 9.2 meter since 2019.

Above all, we and Econotherm can help you recover this wasted heat and put it to good use, saving you money and helping the environment at the same time.