Biotech & Biomass Factory Energy-Saving Technology: Applications of Heat Pipe & Spiral Plate Heat Exchangers

Current Challenges

-

Direct Discharge of High-Temperature Exhaust Gas & Steam, causing severe heat loss

-

High Energy Consumption in processes like fermentation, sterilization, and drying

-

Traditional Heat Exchangers Prone to Scaling, reducing efficiency and requiring frequent maintenance

Improvement Strategies

-

Install Heat Pipe & Spiral Plate Heat Exchangers to enhance waste heat recovery

-

Reduce Fuel & Steam Consumption, lowering production costs

-

Minimize Heat Exchanger Maintenance Needs, improving equipment uptime

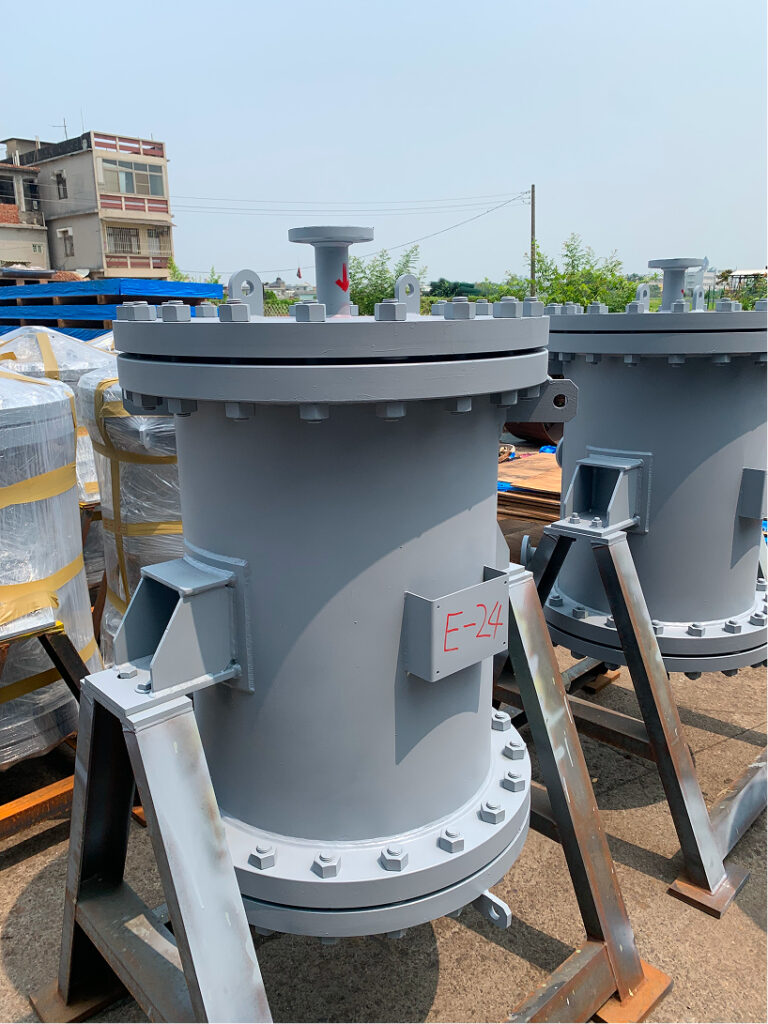

Spiral Plate Heat Exchanger

-

Applications

1. High temperature steam condensation (reducing steam loss)

2. Process heating/cooling (such as hot oil/water cooling)

3. Sewage / high viscosity fluid heat exchange (good self-cleaning effect)

-

Advantages

✅ High efficiency heat exchange, improving steam and hot water recovery efficiency

✅ High efficiency heat exchange, improving steam and hot water recovery efficiency

✅ Compact Size: Suitable for limited installation spaces

✅ Suitable for corrosive fluids, stainless steel or anti-corrosion materials available